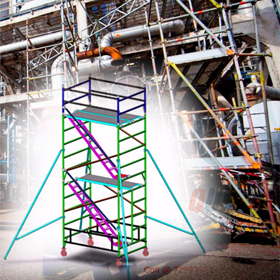

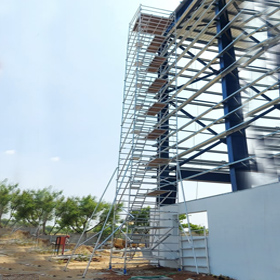

Aluminium Scaffolding Working Height 8m

Aluminium Scaffolding Used For High-Level Indoor Maintenance

We deliver world-class aluminium scaffolding solutions designed for maximum safety, strength, and efficiency. Our aluminium scaffolding systems are ideal for high-level indoor and outdoor maintenance, industrial installations, MEP works, roofing, and facility management projects.

Our mobile aluminium scaffolding system, engineered to provide stable access at extreme heights while ensuring worker safety and ease of movement. Lightweight yet robust, our scaffolding enables quick assembly, smooth relocation, and reliable performance in complex environments such as auditoriums, industrial sheds, malls, and institutional buildings.

| Model No | 5300 |

| Working Height | 8 Meter |

| Platform Height | 6 Meter |

| Width | 1.4 Meter |

| Length | 2.0 Meter |

| Working Condition | Indoor & Outdoor |

| Availability | Sales & Rental |

| Rating |

Aluminium scaffolding plays a critical role across industries by providing safe, stable, and efficient access to elevated work areas. The scaffolding system shown above is designed for high-reach indoor applications, making it ideal for maintenance, installation, inspection, and repair works in complex industrial and commercial environments.

Safety is never optional in industrial environments. Our 8 meter movalbe aluminium scaffolding is designed with 100% safety compliance in mind, integrating multiple protective elements to safeguard workers at height.

These are modular systems and allows sub-assemblies to be easily installed on location, with no downtime to workflows. Our services in Chennai, bangalore, ahmedabad, pune, hyderabad, Tada, delhi.

Manufacturing & Industrial Plants

- Overhead equipment installation and maintenance.

- Roof structure inspection and repairs.

- HVAC ducting, cable trays, and lighting systems.

- Machinery servicing at elevated heights.

- Diagonal and horizontal bracing for rigidity.

The 8m aluminium scaffolding with a total weight of 255.2 KG is the ultimate solution for outdoor work. It is easy to move, quick to dismantle, and safe for all types of job sites. At Sendhamarai Engineering Pvt. Ltd., we provide engineered aluminium scaffolding systems tailored to the unique needs of each industry. Our solutions ensure maximum safety, efficiency, and reliability across all high-access applications.

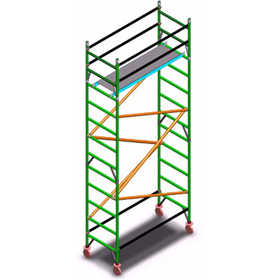

Aluminium Scaffolding Working Height 8m

Aluminium Scaffolding Platform

We present the 8 meter working height aluminium scaffolding, engineered to meet the demanding needs of industrial users, warehouse erection projects, and large indoor facilities. Designed with a lightweight yet heavy-duty aluminium structure, this scaffolding system delivers exceptional strength, superior safety, and unmatched mobility, all within a total weight of 255 kg. For industries that value efficiency, safety, and long-term performance, this aluminium scaffolding solution sets a new benchmark.

The 5300 model offers 8 meter working height aluminium scaffolding is purpose-built for professionals who require safe access at medium heights without compromising stability. The tower structure is fabricated using high-strength aluminium alloy, ensuring maximum load-bearing capacity while remaining easy to handle on-site.

| Model No | 5300 |

| Working Height | 8 Meter |

| Platform Height | 6 Meter |

| Width | 1.4 Meter |

| Length | 2.0 Meter |

| Working Condition | Indoor & Outdoor |

| Availability | Sales & Rental |

| Rating |

The design supports continuous industrial usage, especially in warehouse erection work, manufacturing plants, power facilities, and large infrastructure projects. Even at full height, the scaffold maintains excellent rigidity and balance, ensuring safe operation for workers and tools.

Safety is never optional in industrial environments. Our 8 meter aluminium scaffolding is designed with 100% safety compliance in mind, integrating multiple protective elements to safeguard workers at height.

These are modular systems and allows sub-assemblies to be easily installed on location, with no downtime to workflows. Our services in Chennai, bangalore, ahmedabad, pune, hyderabad, Tada, delhi.

100% Safety-Focused Scaffolding System

- Anti-slip aluminium working platform.

- Full-height guardrails on all sides.

- Toe boards to prevent tool fall.

- High-load castor wheels with locking brakes.

- Diagonal and horizontal bracing for rigidity.

The 8m aluminium scaffolding with a total weight of 255.2 KG is the ultimate solution for outdoor work. It is easy to move, quick to dismantle, and safe for all types of job sites. Its lightweight design, durability, and weather resistance make it a cost-effective choice for construction companies, maintenance crews, and industrial operations looking for maximum efficiency and safety.

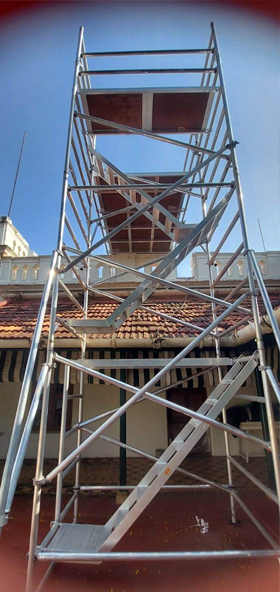

10m Aluminium Scaffolding Outdoor Work

Wheel Scaffolding Platform

Working at heights can be challenging, but the 10m aluminium scaffolding 5300 system is designed to make it safe, efficient, and hassle-free. Whether you are in construction, maintenance, or industrial operations, this lightweight yet durable scaffolding is ideal for all outdoor work. With a total weight of 229.4 KG, it is easy to transport, set up, and dismantle, saving both time and money.

The 5300 model offers a working height of 10 meters, making it suitable for a wide range of outdoor projects. From façade repairs to painting, MEP installation, and roofing, the extended reach ensures workers can access higher elevations without additional equipment.

| Model No | 5300 |

| Working Height | 10 Meter |

| Platform Height | 8 Meter |

| Width | 1.4 Meter |

| Length | 2.0 Meter |

| Working Condition | Indoor & Outdoor |

| Availability | Sales & Rental |

| Rating |

Aluminium scaffolding has become the go-to choice for many professionals because of its strength-to-weight ratio and rust-resistant properties. Unlike steel scaffolding, aluminium is light, easy to handle, and does not corrode when exposed to outdoor weather conditions. This means lower maintenance costs and longer service life.

Advantages of Using Aluminium Scaffolding for Outdoor Work

Outdoor work requires equipment that is strong, reliable, and portable. The 10m aluminium scaffolding meets all these requirements while also being easy to maintain and cost-effective. It is perfect for environments where scaffolding needs to be moved frequently and used in different locations.

These are modular systems and allows sub-assemblies to be easily installed on location, with no downtime to workflows. Our services in Chennai, bangalore, ahmedabad, pune, hyderabad, anantapur, delhi.

Applications in Industrial and Commercial Projects

- Building construction and civil work.

- Electrical and MEP installations.

- Painting and exterior cleaning.

- Warehouse maintenance.

- Event setup and signage installation

The 10m aluminium scaffolding with a total weight of 317.6 KG is the ultimate solution for outdoor work. It is easy to move, quick to dismantle, and safe for all types of job sites. Its lightweight design, durability, and weather resistance make it a cost-effective choice for construction companies, maintenance crews, and industrial operations looking for maximum efficiency and safety.

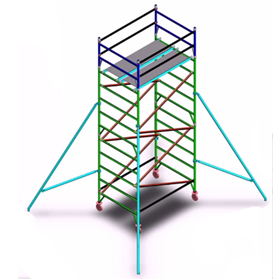

14m Aluminium Scaffolding Rental

Movable Scaffolding Platform

The 5300 aluminium scaffolding model has emerged as a trusted solution for construction, industrial, and infrastructure projects that demand both high safety standards and ease of use in outdoor environments. With a working height of 14 meters, this scaffolding system ensures that even the most challenging tasks at height can be performed with confidence. Its compact design, durable aluminium build, and advanced safety features make it an ideal choice for outdoor applications across all project types, from civil engineering to facility maintenance.

The 5300 model offers a working height of 14 meters, making it suitable for a wide range of outdoor projects. From façade repairs to painting, MEP installation, and roofing, the extended reach ensures workers can access higher elevations without additional equipment.

| Model No | 5300 |

| Working Height | 14 Meter |

| Platform Height | 12 Meter |

| Width | 1.4 Meter |

| Length | 2.0 Meter |

| Working Condition | Indoor & Outdoor |

| Availability | Sales & Rental |

| Rating |

Safety is the foundation of the 5300 aluminium scaffolding model. Working outdoors at great heights requires robust protection against slips, falls, and instability, and this model is designed to exceed industry expectations.These safety features make the 5300 model a trusted choice for contractors who prioritize worker well-being while maintaining project efficiency.

One of the biggest advantages of the 5300 aluminium scaffolding is its compact design, which enables easy transport and storage. Outdoor projects often require frequent relocation of scaffolding between different job sites, and the 5300 model makes this process seamless. We are stocked our aluminium scaffolding rental in chennai, bangalore, hyderabad, delhi, pune, ahmedabad, Tada. For rental purpose we service anywhere in india.

These are modular systems and allows sub-assemblies to be easily installed on location, with no downtime to workflows. Our services in Chennai, bangalore, ahmedabad, pune, hyderabad, anantapur, delhi.

- Non-slip platforms provide stability even in wet or dusty outdoor conditions.

- Guardrails and toe boards are integrated to protect workers from accidental falls.

- Lockable castor wheels ensure secure positioning, even on uneven ground.

- Diagonal bracing enhances rigidity, minimizing sway during high-level work.

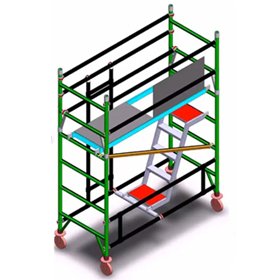

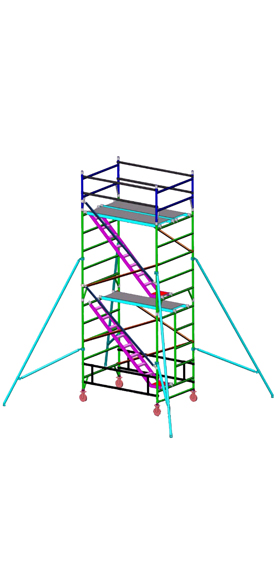

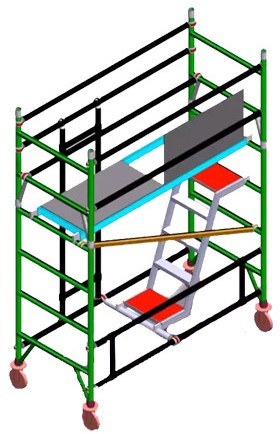

Aluminium Scaffolding Rental

Industrial Equipment Supplier

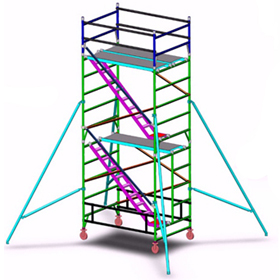

We are offering our clients the best Scaffold Tower Aluminium with Stairway. Developed by making use of supreme quality aluminium and other required basic material, these offered ladders are in compliance with the defined quality parameters of the industry.

The stairway scaffolding provides optimum safety owing to its staircase system, along with handrail feature. It is ideal for large load capacity climbing in addition to allowing access to elevated heights.

| Working Condition | Both Indoor & Outdoor |

| Scaffolding Availability | Available For Both Sales & Rental |

| Rating |

Aluminium Scaffolding Models

Stairway Platform System can be customized and widely used as elevated work platforms, industrial/warehouse mezzanines, Inspection areas around large and non-standard applications in factories, renting facilities and automation cells or assembly operations.We also provide site surveys and assessment of any access problems, where our scaffolding products may offer a viable and practical access solutions drawing upon our years of experience from previous scenarios & applications. Our product range has components which are unique in the features they offer to the customer . We are stocked our aluminium scaffolding rental in chennai, bangalore, hyderabad, delhi, pune, ahmedabad, Tada. For rental purpose we service anywhere in india.

These are modular systems and allows sub-assemblies to be easily installed on location, with no downtime to workflows. Our services in Chennai, bangalore, ahmedabad, pune, hyderabad, anantapur, delhi.

- Easily assembled in the customer's facility.

- Eeasy Portability

- Light Weight and easy handling

- It utilized for all industrial and commercial work.

- Up to 20 Meters available for sales and service.

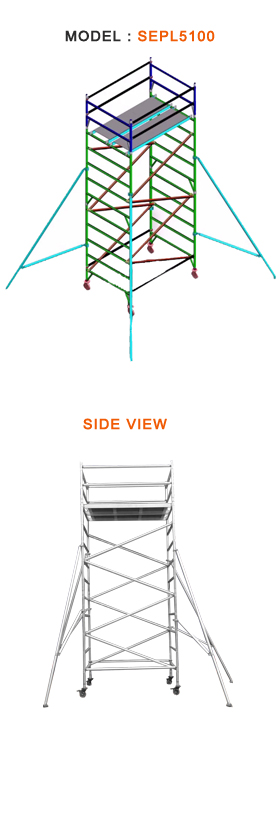

16m Aluminium Scaffolding Model 5100

At the forefront of modern access solutions, the Aluminium Scaffolding Model 5100 by Sendhamarai Engineering has redefined the standards for height safety and mobility in construction, industrial maintenance, and commercial facility management. With a working height of up to 16 meters and designed with heavy-duty wheels, this model is an ideal choice for professionals seeking durability, lightweight performance, and versatile application. Available for sale, rental, and direct manufacturing, this scaffolding model delivers unmatched utility and safety features for high-reach workspaces.

High Reach Capability – Up to 16 Meters Working Height

The Aluminium Model 5100 scaffolding system is built to reach up to 16 meters, providing access for tasks like façade painting, HVAC installations, lighting maintenance, and industrial cleaning. The tower height is customizable in increments, allowing the user to configure the platform height based on site requirements.Durable and Lightweight Aluminium Scaffolding

Industrial using high-grade aluminium alloy, the scaffolding system is both corrosion-resistant and lightweight. The alloy ensures structural integrity under load while simplifying transportation and setup. Compared to steel scaffolding, aluminium offers faster assembly without compromising on strength.Wheel Type Mobile Scaffolding with Locking Mechanism

Equipped with heavy-duty caster wheels, the Model 5100 enables seamless mobility across flat surfaces. Each wheel includes a dual-lock system to ensure the structure remains securely in place during operation. These industrial-grade wheels are designed to support dynamic loads, offering stability and ease of repositioning.Sales: Purchase Options for Aluminium Scaffolding 5100

The Model 5100 is available for outright purchase, with customization options based on client needs. Buyers can choose from standard height variants including 4m, 8m, 12m, and 16m platforms. Add-ons like ladder frames, extended outriggers, and adjustable platforms can be bundled for industry-specific requirements.- Warranty of up to 1 years

- Free on-site installation training

- Spare parts availability

- Post-sales servicing contracts

Aluminium Scaffolding Team

The Aluminium Scaffolding Model 5100 by Sendhamarai Engineering offers a unique combination of high-reach access, mobility, and safety. Whether you are looking to purchase, rent, or source from a manufacturer, this model is designed to meet demanding industrial and commercial standards. Its adaptability across sectors, together with premium build quality, makes it a leading solution in the scaffolding market. We are stocked our aluminium scaffolding rental in chennai, bangalore, hyderabad, delhi, pune, ahmedabad, Tada. For rental purpose we service anywhere in india.

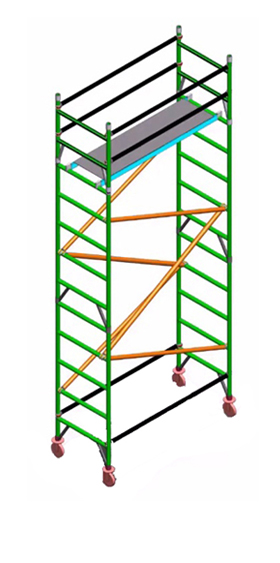

Aluminium Mobile Scaffolding Model 5150

When it comes to safe, portable, and high-quality access solutions, the Aluminium Scaffolding Model 5150 stands out as a top-tier choice. Designed with mobility, flexibility, and sturdy height performance, this model is trusted across industries for light to moderate elevation needs.

Aluminium scaffolding is a modern, lightweight alternative to traditional steel scaffolding. Built for ease of movement, quick installation, and high resistance to environmental wear, it's ideal for various temporary access applications.

The Model 5150 is specifically engineered for projects requiring a working height of up to 6 meters. Its compact build and wheel-type mobility make it perfect for both indoor and outdoor environments with frequent repositioning.

Specification

| Platform Height | Working Height |

| 1.8 Mtr | 3.6 Mtr |

| 2.2 Mtr | 4.0 Mtr |

| 3.6 Mtr | 5.4 Mtr |

| 4.2 Mtr | 6.0 Mtr |

| Customer Rating |

The Aluminium Scaffolding Model 5150 is a versatile, mobile, and durable access solution perfect for various industrial and commercial applications. With a working height of up to 6 meters, robust safety features, and user-friendly setup, it provides everything professionals need in a compact form. Whether you're looking to rent or buy, this model offers great value and unmatched convenience.

Working Height – Up to 19.6 Feet : This model allows you to safely operate at up to 46 feet in working height, suitable for high-roofed structures and multi-storey applications.

Platform Width – 800mm : The extra-wide 800mm width provides ample space for technicians and tools, increasing productivity and reducing the number of climbs up and down.

Platform Length – 2000mm : With a 2000mm platform length, workers can comfortably maneuver across the work area without repositioning the scaffolding constantly.

Load Capacity : Each platform is rated for 250–300 kg, ensuring multiple workers and equipment can work together safely.

5300 Scaffolding Application

- Construction and building maintenance.

- Power plants and turbine access.

- Oil & gas refineries.

- Warehouse logistics & ventilation systems.

- Mall ceiling and lighting.

- Billboard or signage setup

- AC and duct maintenance

- Stage setup for events

We are stocked our aluminium scaffolding rental in chennai, bangalore, hyderabad, delhi, pune, ahmedabad, Tada. For rental purpose we service anywhere in india.

Aluminium Scaffolding Model - SEPL 5300

When it comes to working at height, safety and efficiency are non-negotiable. Whether you're handling a major construction project or need to perform regular maintenance at an industrial site, choosing the right scaffolding can make or break your workflow. That’s where aluminium scaffolding comes into play—lightweight, corrosion-resistant, and built for versatility.

We’re proud to introduce the SEPL5300 aluminium scaffolding model, designed for industrial and commercial use, with a massive working height of up to 46 feet. It’s a robust solution engineered to meet the demands of professionals who work high and need a stable, mobile, and modular platform.

Specification

| Platform Height | Working Height |

| 2.2 Mtr | 4.0 Mtr |

| 4.2 Mtr | 6.0 Mtr |

| 6.2 Mtr | 8.0 Mtr |

| 8.2 Mtr | 10.0 Mtr |

| 10.2 Mtr | 12.0 Mtr |

| 12.2 Mtr | 14.0 Mtr |

| 14.2 Mtr | 16.0 Mtr |

| Customer Rating |

We are stocked our aluminium scaffolding rental in chennai, bangalore, hyderabad, delhi, pune, ahmedabad, Tada. For rental purpose we service anywhere in india.

Aluminium Scaffolding In Working Site

The SEPL5300 is our flagship model tailored for large-scale access applications. Whether you're a facilities manager, a contractor, or managing a warehouse or refinery, this system is built for reliability and performance. It combines rugged engineering with a streamlined setup process, making it ideal for both sales and rentals.

Working Height – Up to 46 Feet : This model allows you to safely operate at up to 46 feet in working height, suitable for high-roofed structures and multi-storey applications.

Platform Width – 1400mm : The extra-wide 1400mm width provides ample space for technicians and tools, increasing productivity and reducing the number of climbs up and down.

Platform Length – 2000mm : With a 2000mm platform length, workers can comfortably maneuver across the work area without repositioning the scaffolding constantly.

Load Capacity : Each platform is rated for 250–300 kg, ensuring multiple workers and equipment can work together safely.

5300 Scaffolding Application

- Construction and building maintenance.

- Power plants and turbine access.

- Oil & gas refineries.

- Warehouse logistics & ventilation systems.

- Mall ceiling and lighting.

- Billboard or signage setup

- AC and duct maintenance

- Stage setup for events

We are stocked our aluminium scaffolding rental in chennai, bangalore, hyderabad, delhi, pune, ahmedabad, Tada. For rental purpose we service anywhere in india.

Aluminium Scaffolding Model - SEPL 5250

Aluminium scaffolding is a temporary structure used to support people and materials during construction or maintenance. Thanks to its lightweight yet durable nature, aluminium is ideal for quick, safe indoor access to elevated areas.

Unlike steel, aluminium doesn’t rust, is easier to move, and doesn’t damage floors. It’s perfect for indoor tasks like lighting work, HVAC installation, and painting—especially in tight spaces. Model 5150 is designed for compact indoor environments. With non-marking wheels, foldable frames, and tool-less assembly, it stands out as the go-to solution for maintenance teams and facility managers.

Specification

| Platform Height | Working Height |

| 1.8 Mtr | 3.6 Mtr |

| Customer Rating |

Light weight but durable : Thanks to the aerospace-grade aluminium, it’s strong yet light enough to move single-handedly.

Easy to assemble and dismantle : Snap-locks, folding braces, and color-coded frames make setup effortless—even for first-timers.

Time-saving for short-term tasks : You don’t waste time hauling heavy equipment or waiting on lift operators. Model 5150 is ready to go.

Key Features of Model 5150 Scaffolding

- 360° rotation.

- Double brake system.

- Non-scuffing rubber tires for delicate indoor floors.

- False ceiling jobs.

- Wall air conditioner installations.

- Billboard or signage setup

- AC and duct maintenance

- Stage setup for events

Aluminium Scaffolding Model 5150 is the perfect fit for compact indoor work environments. Its lightweight frame, foldable design, and 3.6m working height make it the go-to choice for electricians, facility managers, and interior maintenance teams. Whether you're renting or buying, ensure safety is never compromised. A stable scaffold means a safer and more productive job site.

We are stocked our aluminium scaffolding rental in chennai, bangalore, hyderabad, delhi, pune, ahmedabad, Tada. For rental purpose we service anywhere in india.

Customised Aluminium Scaffolding for Home Purpose

Aluminium scaffolding is revolutionizing how we tackle home improvement projects. Traditionally, scaffolding was reserved for large-scale commercial construction sites, but now, thanks to the introduction of lightweight and customisable materials like aluminium, homeowners are finding it easier than ever to access and complete those hard-to-reach tasks around the house. But why has aluminium scaffolding become so popular, and how does customization make it the perfect tool for home use?

Why Choose Aluminium for Scaffolding?

Aluminium offers a range of benefits that make it ideal for scaffolding, especially for domestic purposes.Lightweight yet Strong: One of the primary reasons for the rise in the use of aluminium scaffolding is its lightweight nature. Unlike steel scaffolding, aluminium is much easier to move around, making it perfect for DIYers and homeowners who want to avoid the hassle of handling heavy materials.

Corrosion Resistance: Another benefit of aluminium is that it doesn’t rust, even when exposed to moisture. This makes it suitable for both indoor and outdoor projects, whether you're cleaning gutters or repainting the exterior of your home.

Key Features of Customised Aluminium Scaffolding

Some of the key features to look for in customised scaffolding include:Adjustable Heights: You can modify the height based on the task at hand. This flexibility is essential for home projects, where you may need to reach different levels without swapping scaffolding.

Compact Storage: Unlike traditional scaffolding, aluminium models are often foldable or collapsible, making storage easier in a garage or shed.

Final Statement about Customised Scaffolding

Customised aluminium scaffolding is the perfect solution for homeowners looking to complete DIY projects safely and efficiently. Lightweight, durable, and easy to use, it's no wonder that aluminium scaffolding has become the go-to choice for both professionals and amateur handymen alike.

We are stocked our aluminium scaffolding rental in chennai, bangalore, hyderabad, delhi, pune, ahmedabad, Tada. For rental purpose we service anywhere in india.

Aluminium Mobile Scaffolding Tower Work in Commercial Unit

In the fast-paced world of commercial units, efficiency and safety are paramount. One tool that plays a crucial role in ensuring these two factors is the aluminium mobile scaffolding tower. But what exactly is an aluminium mobile scaffolding tower, and why is it so essential in commercial environments?

What Are Aluminium Mobile Scaffolding Towers?

Aluminium mobile scaffolding towers are temporary, portable structures used to support workers and materials during construction, maintenance, or repair work. Made from lightweight yet durable aluminium, these towers are designed for easy mobility, allowing workers to move them to different locations as needed.

Importance in Commercial Units :-

In commercial units, where tasks often involve working at heights, aluminium mobile scaffolding towers offer a safe and stable platform for various activities. From routine maintenance to large-scale construction projects, these towers are indispensable, ensuring that workers can perform their tasks efficiently and without unnecessary risk.

Advantages of Using Aluminium Mobile Scaffolding Towers

Lightweight and Portable

One of the standout features of aluminium scaffolding towers is their lightweight nature. Unlike traditional steel scaffolding, aluminium towers can be easily transported and set up by a small team, making them ideal for commercial units where time and space are often limited.

Easy Transportation and Setup

The portability of aluminium scaffolding towers means they can be quickly moved from one location to another, reducing downtime between tasks. This feature is especially beneficial in commercial units where multiple projects may be happening simultaneously.

Durability and Strength

Despite their lightweight design, aluminium scaffolding towers are incredibly strong and durable. They can withstand heavy loads and harsh working conditions, making them a reliable choice for long-term use.

Corrosion Resistance and Longevity

Aluminium is naturally resistant to corrosion, meaning these towers can be used in various environments without the risk of rust or deterioration. This resistance ensures that the towers remain in good condition for longer, providing excellent value for money.

We are stocked our aluminium scaffolding rental in chennai, bangalore, hyderabad, delhi, pune, ahmedabad, Tada. For rental purpose we service anywhere in india.

Aluminium Scaffolding Manufacturers

Aluminium Scaffolding Rental Price

If you do not have durability and complete maintenance, choose aluminium scaffolding manufacturers are ideal for operations at heights where it is not necessary to stand for more than 10-20 minutes. For longer operations, choose an aluminium scaffold rental. Let check the aluminium scaffolding in details.

Regular access Aluminium scaffolding.

This type is best for general purpose when your group needs access to the base. Choose the right height. In general, aluminium scaffolding has a quick construction time compared to other types because of the many safety components. You can find these types of aluminium scaffolding tower at most equipment rental companies. Aluminium scaffolding is suitable for use in industrial work , Interior works, MEP, HVAX, PEB, Commercial, maintenance job is more compact to work & cost saving products.

Our provided Aluminium Mobile Scaffolding tower Stair case is widely appreciated by our prestigious clients for its precise design and easy installation. This tower can also be availed in various sizes, designs and other related specifications. Our provided tower is manufactured by a team of our adept professionals utilizing quality approved stainless steel and advanced technology.

| Working Condition | Both Indoor & Outdoor |

| Scaffolding Availability | Available For Both Sales & Rental |

| Rating |

Aluminium Scaffolding Rental Works In Mall

In the realm of modern construction and maintenance, aluminium scaffolding has emerged as a pivotal tool, especially in the context of large commercial spaces like malls. The versatility, durability, and safety features of aluminium scaffolding make it an indispensable asset for various tasks, ranging from construction and renovation to regular maintenance. In this article, we delve into the myriad benefits and applications of aluminium scaffolding rental works in malls, shedding light on why it is the preferred choice for contractors and facility managers alike.

Advantages of Aluminium Scaffolding

Lightweight and Portable

One of the most significant advantages of aluminium scaffolding is its lightweight nature. This characteristic makes it easy to transport and maneuver within the confined and often crowded spaces of a mall. Unlike traditional steel scaffolding, aluminium scaffolding can be quickly assembled and disassembled, saving valuable time and reducing labor costs.

Durability and Strength

Despite being lightweight, aluminium scaffolding does not compromise on strength. It can support substantial weights, ensuring that workers can safely carry out their tasks. The material's inherent resistance to corrosion also means that it remains in excellent condition over long periods, even when subjected to varying environmental conditions within a mall.

Safety and Stability

Safety is a paramount concern in any construction or maintenance activity, and aluminium scaffolding excels in this aspect. The scaffolding is designed with features such as non-slip platforms and guardrails, providing a secure working environment. The stability of aluminium scaffolding ensures that it does not wobble or tip over, minimizing the risk of accidents.

Aluminium Scaffolding Works In Commercial Places

Construction Sites

Aluminium scaffolding is widely used in construction sites across Bangalore. Its versatility and ease of assembly make it suitable for various construction activities, from building new structures to renovating existing ones.

Maintenance and Repairs

Commercial buildings require regular maintenance and repairs to remain functional and safe. Aluminium scaffolding provides a secure platform for workers to perform these tasks efficiently and safely.

Retail and Shopping Malls

In retail environments, such as shopping malls, aluminium scaffolding is often used for installing signage, lighting, and other fixtures. Its lightweight nature allows for easy movement and positioning, making it an ideal choice for these settings.

Office Buildings

Office buildings often undergo renovations and upgrades to keep up with modern standards. Aluminium scaffolding is essential in these projects, providing a stable and reliable structure for workers to perform their tasks.

Customised Aluminium Scaffolding In Construction

Now a day commercial and industrial sectors, customised aluminium mobile scaffolding has emerged as a game-changer in construction, maintenance, and other commercial applications. With its lightweight structure, durability, mobility, and flexibility, aluminium scaffolding offers businesses an efficient solution for working at heights while ensuring maximum safety and productivity.

Lightweight Yet Durable Structure : -

Unlike traditional steel scaffolding, aluminium scaffolding is significantly lighter, making it easy to move and transport. Despite being lightweight, high-quality aluminium alloys provide exceptional durability and strength, ensuring long-term performance under demanding commercial conditions. This feature is crucial in high-rise commercial buildings, warehouses, and industrial setups where frequent movement of scaffolding is required.

Easy Mobility and Quick Assembly : -

Time is money in commercial projects, and aluminium mobile scaffolding significantly reduces downtime. The built-in wheels and quick-locking mechanisms enable smooth mobility across work sites. Customised scaffolding can be easily adjusted and reassembled to fit different project needs, allowing workers to transition from one task to another without unnecessary delays.

Corrosion Resistance and Low Maintenance : -

One of the biggest advantages of aluminium scaffolding is its natural resistance to rust and corrosion. Unlike steel, which requires regular maintenance and protective coatings, aluminium scaffolding remains unaffected by harsh weather conditions, making it ideal for outdoor commercial applications such as billboard installations, facade maintenance, and window cleaning.

Commercial Building Maintenance & Repairs : -

Routine maintenance is essential for commercial properties such as hotels, shopping malls, and office buildings. Aluminium mobile scaffolding enables workers to perform plumbing, electrical, and HVAC repairs efficiently without the need for permanent installations.

We are stocked our aluminium scaffolding rental in chennai, bangalore, hyderabad, delhi, pune, ahmedabad, Tada. For rental purpose we service anywhere in india.

How to Choose the Right Aluminium Scaffolding

Assessing Project Needs

When selecting aluminium scaffolding, it is essential to assess the specific needs of the project. Factors such as height requirements, load capacity, and site conditions should be considered.

Evaluating Quality and Safety Features

Ensure that the aluminium scaffolding meets the required quality and safety standards. Look for features such as non-slip platforms, safety rails, and stabilizers to enhance worker safety.

Cost Considerations

While cost is an important factor, it should not be the sole deciding factor. Consider the long-term benefits and cost savings of using high-quality aluminium scaffolding.

Technological Advancements

Technological advancements are continuously improving the design and functionality of aluminium scaffolding. Innovations such as modular designs and enhanced safety features are making aluminium scaffolding even more efficient and reliable.

Increased Adoption in Commercial Projects

As the benefits of aluminium scaffolding become more widely recognized, its adoption in commercial projects is expected to increase. More contractors and builders are likely to choose aluminium scaffolding for its numerous advantages.

We are stocked our aluminium scaffolding rental in chennai, bangalore, hyderabad, delhi, pune, ahmedabad, Tada. For rental purpose we service anywhere in india.