Table of Contents

Aluminium Tower scaffolding has changed the way businesses approach elevated workspaces. The Aluminium Tower Scaffolding Model 5300 is one such revolutionary solution offering unmatched performance, particularly in industrial and commercial environments. With a working height of 8 meters and a platform height of 6.2 meters, this mobile tower provides safe, reliable, and elevated access to hard-to-reach areas while being extremely easy to transport and assemble.

In this comprehensive article, we’ll dive into everything you need to know about the Aluminium Tower Scaffolding Model 5300—from its key features and technical specs to its ideal use cases, safety protocols, and frequently asked questions.

Introduction to Aluminium Tower Scaffolding Model 5300

Aluminium tower scaffolding is fast becoming the preferred choice in construction, maintenance, and industrial setups. The Model 5300 offers a practical solution where ladders fall short and traditional steel scaffolding proves too heavy or cumbersome.

What sets this model apart is its 8-meter working height and 6.2-meter platform level, designed to provide elevated access with safety, durability, and simplicity in setup. Whether you’re fixing electrical wiring in a commercial facility or inspecting a factory ceiling, this tower has your back.

Key Features of Model 5300

The Aluminium Tower Scaffolding Model 5300 is packed with features to make your work smoother and safer:

- High-Strength Aluminium Frame: Lightweight yet tough, ensuring portability and long-term use.

- Wheel-Based Mobility: Includes heavy-duty, lockable castor wheels for easy repositioning.

- Non-Slip Platforms: The working platform is made from anti-slip material for added worker safety.

- Compact Footprint: Designed to fit through standard doors and corridors.

- Modular Design: Easy to dismantle and reassemble, making it ideal for rental services or frequent transportation.

These features are built to optimize both performance and convenience, saving time and reducing physical strain on workers.

Technical Specifications

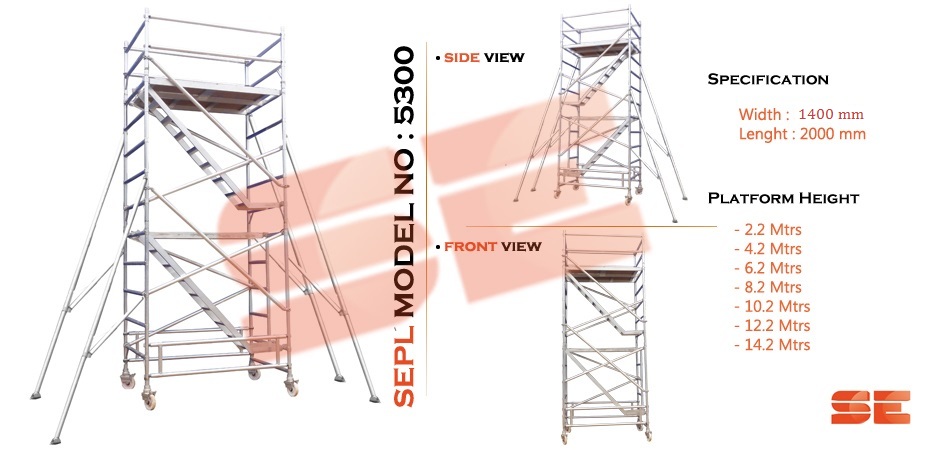

Understanding the specs of the Model 5300 helps determine its fitness for your project:

- Working Height: 8 meters

- Platform Height: 6.2 meters

- Platform Size: 1400mm (width) × 2000mm (length)

- Frame Material: Aluminium Alloy 6061-T6

- Load Capacity: 225 kg per platform

- Number of Castor Wheels: 4 (lockable)

- Compliance: Meets EN1004, OSHA, and ANSI standards

This scaffold model is a robust piece of equipment that supports heavy-duty use while maintaining flexibility in movement and installation.

Industrial Applications

The Model 5300 is particularly valuable in industrial environments where elevated access is critical but conditions vary:

- Factories and Manufacturing Plants: Perfect for maintenance of overhead machinery and systems.

- Warehouses: Helps in organizing, checking, or repairing high racks and lighting.

- Oil & Gas Facilities: Used for inspections, pipework adjustments, and cleaning.

- Power Plants: Essential for working on electrical infrastructure safely.

Its modularity and resilience in extreme environments make it a go-to option for industry pros.

Commercial Applications

Commercial buildings often require height-access solutions for repairs, installations, and interior redesigns. The Aluminium Tower Scaffolding Model 5300 is ideal for:

- Shopping Malls: For lighting maintenance or display changes.

- Office Buildings: Facilitates HVAC servicing, ceiling fixes, or painting jobs.

- Airports and Stations: Used in signage installation and structural inspections.

- Educational Institutions: Useful in auditoriums, sports complexes, or library areas.

Being lightweight and mobile, it can be easily moved between rooms or levels via elevators and corridors.

Advantages of Aluminium Over Steel Scaffolding

Why choose aluminium over steel? Here are a few convincing reasons:

- Corrosion Resistance: Aluminium doesn’t rust, making it ideal for outdoor and humid conditions.

- Lightweight: Easy to transport and install by a small team.

- No Welding Required: Quick-connect systems save time and reduce setup risks.

- Less Maintenance: Steel requires regular painting or anti-rust treatment; aluminium does not.

- Eco-Friendly: Aluminium is recyclable and leaves a lower environmental footprint.

In summary, aluminium Tower scaffolding combines durability with efficiency and environmental responsibility.

Assembly and Setup Guide

Setting up Model 5300 is straightforward and doesn’t require special tools:

- Lay the base frames and lock the wheels.

- Insert horizontal and diagonal braces for stability.

- Stack vertical frames to reach the desired height.

- Add the platform at 6.2 meters.

- Secure with guardrails and toe boards.

Make sure every component locks into place before climbing. Always refer to the instruction manual and follow local safety regulations.

Safety Features and Certifications

Safety is the backbone of scaffolding design, and Model 5300 delivers:

- Non-Slip Surface: Prevents accidental slips while working.

- Toe Boards and Guardrails: Prevents tools and people from falling.

- Wheel Locks: Keeps the scaffold stationary during use.

- Safety Certifications: Complies with EN1004, ANSI, and OSHA for workplace safety.

Users are also encouraged to use proper PPE (Personal Protective Equipment) and undergo scaffolding safety training.

Maintenance and Storage Tips

To keep your Aluminium Tower Scaffolding Model 5300 in peak condition:

- Inspect Weekly: Check for bent tubes, loose locks, or worn platforms.

- Clean Regularly: Use a mild detergent and soft cloth. Avoid acidic cleaners.

- Dry Before Storage: Moisture can damage rubber wheels and weaken connectors.

- Store Indoors: Preferably in a dry, ventilated area on a rack or pallet.

Routine checks prolong the life and safety of the unit.

Where to Buy or Rent Model 5300

We offer both sales and rentals depending on your project timeline:

- Short-Term Projects: Go for rental options—cheaper and worry-free.

- Long-Term Use: Buying pays off in the long run and provides always-ready access.

- Nationwide Delivery: Fast shipping and on-site setup assistance available.

Choose us for quality assurance, affordable pricing, and after-sales support.

Conclusion

When it comes to working at height, safety and efficiency are non-negotiable. Whether you’re handling a major construction project or need to perform regular maintenance at an industrial site, choosing the right scaffolding can make or break your workflow. That’s where aluminium tower scaffolding comes into play—lightweight, corrosion-resistant, and built for versatility.

We’re proud to introduce the SEPL 5300 aluminium tower scaffolding model, designed for industrial and commercial use, with a massive working height of up to 46 feet. It’s a robust solution engineered to meet the demands of professionals who work high and need a stable, mobile, and modular platform.

The Aluminium Tower Scaffolding Model 5300 is more than just a platform—it’s a productivity booster, a safety upgrade, and a long-term solution for reaching challenging heights in industrial and commercial settings. Whether you’re working in a large factory, a buzzing commercial hub, or a tightly packed warehouse, this model brings the kind of flexibility and reliability that professionals crave.

With its 8-meter working height, mobile design, and modular construction, it simplifies everything from setup to storage. You don’t need a large team, a complex manual, or heavy lifting equipment—just a smart choice and a bit of training.

So, whether you choose to rent it for a quick job or purchase it for long-term use, know that you’re investing in efficiency, safety, and future-ready technology. Don’t let heights slow you down—elevate your work with aluminium tower scaffolding Model 5300.