Hydraulic Scissor Lift Rental

Renting hydraulic scissor lifts offers flexibility and cost-effectiveness. Whether for construction, maintenance, or events, these lifts provide a safe and efficient way to reach elevated spaces.

Advantages of Hydraulic Scissor Lifts

Experience enhanced productivity with hydraulic scissor lifts. These lifts boast stability, easy maneuverability, and the ability to reach varying heights. Elevate your project efficiency with these standout advantages.

Applications of Hydraulic Scissor Lifts

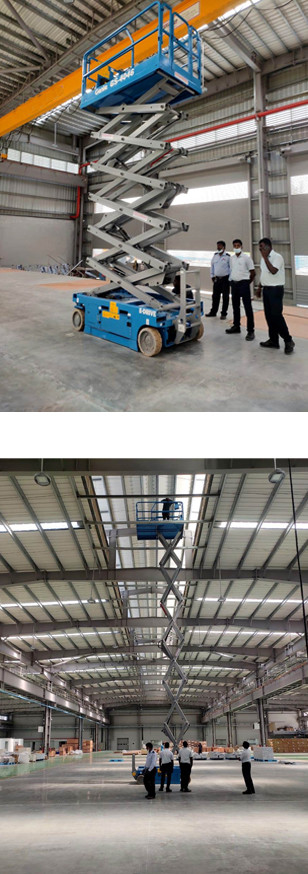

From construction sites to warehouse operations, hydraulic scissor lifts find diverse applications. Discover how these versatile lifts can elevate your specific project needs.

| Working Condition | Indoor Application |

| Machine Availability | Available For Rental |

| Rating |

Realated Work

Cost-Efficiency in Project Budgets

Renting hydraulic scissor lifts proves cost-effective compared to purchasing. Explore how this rental option can contribute to optimizing your project budget without compromising quality..We are stocked our scissor lift in chennai, bangalore, hyderabad, delhi, pune, ahmedabad, Anantapur. For rental purpose we service anywhere in india.

Maintenance and Service

Ensure optimal performance by understanding the maintenance requirements of rented hydraulic scissor lifts. Learn about service expectations and how to address issues promptly for uninterrupted workflow.

- Experience enhanced productivity with hydraulic scissor lifts.

- Scissor lifts boast stability, easy maneuverability, and the ability to reach varying heights.

- Elevate your project efficiency with these standout advantages.

- Prioritize safety when operating hydraulic scissor lifts.

| Max Working Height | 21 ft | 6,57 m |

| Capacity | 600 lb | 272 kg |

| Machine Width | 2 ft 6 in | 0.76 m |

| Weight | 2,575 lb | 1,168 kg |

Hydraulic scissor lift Operations

Industrial maintenance is a critical component of keeping production facilities running smoothly. Whether it's routine repairs, equipment inspections, or emergency interventions, maintenance tasks often require workers to reach elevated areas safely and efficiently. This is where battery-operated scissor lifts come into play. These innovative machines have become indispensable in industrial settings, offering a blend of mobility, safety, and environmental benefits. In this article, we'll explore how battery-operated scissor lifts are transforming industrial maintenance.

Key Features of Battery Operated Scissor Lifts

Mobility and Flexibility :-

Battery-operated scissor lifts are renowned for their mobility. They can easily navigate tight spaces and are well-suited for both indoor and outdoor environments. Their compact design and maneuverability make them ideal for maintenance tasks that require access to multiple areas within a facility.

Energy Efficiency and Environmental Benefits :-

One of the main advantages of battery operated scissor lifts is their energy efficiency. Unlike diesel-powered lifts, they produce no emissions, making them a more environmentally friendly option. Additionally, the absence of combustion engines means they operate quietly, which is beneficial in noise-sensitive environments.

Safety Features :-

Safety is paramount in industrial maintenance, and battery-operated scissor lifts come equipped with a range of features to ensure worker safety. These include non-slip platforms, guardrails, emergency stop buttons, and overload sensors that prevent the lift from operating beyond its capacity.

Applications of Battery Operated Scissor Lifts in Various Industries

Scissor Lift In Manufacturing Plants:-

In manufacturing settings, battery-operated scissor lifts are used to access elevated machinery, perform maintenance on overhead systems, and manage inventory stored at height. Their mobility and compact size make them ideal for navigating the often-crowded spaces in manufacturing plants.

Scissor Lift In Warehouses Unit:-

Warehouses require regular maintenance of lighting systems, ventilation units, and storage racks. Battery-operated scissor lifts provide a safe and efficient way to reach these areas, ensuring that maintenance tasks are carried out without disrupting daily operations.

Scissor Lift In Construction Sites :-

Hydraulic battery operated scissor lifts are also widely used in construction. They are ideal for tasks such as installing windows, painting, and performing electrical work at height. Their quiet operation and zero emissions make them particularly suitable for indoor construction projects or in areas with strict noise and emission regulations.

Increased Productivity :-

Battery-operated scissor lifts enhance productivity by allowing maintenance workers to quickly and safely access high areas. This reduces the time needed to complete tasks, minimizing downtime and keeping production lines running efficiently.

Reduced Operational Costs :-

Battery-operated scissor lifts can lead to significant cost savings over time. They have lower operational costs compared to diesel-powered lifts due to reduced fuel consumption and fewer maintenance requirements. Additionally, they eliminate the need for costly ventilation systems in indoor environments, as they produce no harmful emissions.

Enhanced Worker Safety: -

These lifts are designed with worker safety in mind. Their stable platforms and advanced safety features reduce the risk of accidents, allowing workers to focus on their tasks without worrying about the stability of the lift.

Minimal Environmental Impact: -

With growing concerns about environmental sustainability, battery-operated scissor lifts offer a greener alternative to traditional lifts. They help reduce the carbon footprint of industrial operations by eliminating the use of fossil fuels and minimizing emissions.

- 1. Flexibility and Adaptability

- 2. Cost-Effectiveness

- 3. Enhanced Productivity

- 4. Safety Assurance

- 5. Trial and Error

- 6. Reduced Maintenance Burden

- 7. Accessibility to Advanced Technology

- 8. Environmental Considerations

The role of hydraulic scissor lifts

Hydraulic scissor lifts, marvels of modern engineering, have become indispensable in various industries. Understanding how these lifts operate, especially in different settings like indoor and outdoor environments, is crucial for maximizing their potential.

Scissor Lift Operator Training

Begin by ensuring that all operators undergo comprehensive training before using a scissor lift. Training programs should cover the fundamentals of operating the equipment, understanding safety features, and responding to emergency situations. Competent and knowledgeable operators are the first line of defense in maintaining a secure work environment.

Cost-Effectiveness:

Opting for hydraulic scissor lift rental proves cost-effective compared to purchasing. This is particularly beneficial for short-term projects or those with fluctuating demands for elevated access. By avoiding the upfront costs of ownership, businesses can allocate resources more efficiently, optimizing their overall project budget.

Scissor Lift Indoor Applications :

In confined indoor spaces, the versatility of hydraulic scissor lifts truly shines. These lifts can navigate through tight spaces with ease, making them invaluable for tasks such as maintenance, installations, and repairs within warehouses, manufacturing plants, and retail spaces.

Outdoor Applications:

Taking hydraulic scissor lifts outdoors presents a different set of challenges. Uneven terrain, varying weather conditions, and the need for extended reach require lifts designed to withstand these elements. Outdoor applications include construction projects, landscaping, and maintenance of elevated structures.

Advantages in Each Setting:

The advantages of hydraulic scissor lifts are tailored to the specific needs of indoor and outdoor applications. Indoors, their compact design allows access to hard-to-reach areas, while outdoors, their robust construction and stability contribute to efficient operations even on challenging terrains.

Safety Features :

Safety is paramount in hydraulic lift operations. Features like emergency stop buttons, guardrails, and safety sensors ensure secure operations. Understanding and adhering to safety protocols is crucial for creating a secure work environment.

Maintenance Practices:

Prolonging the life of hydraulic scissor lifts involves regular maintenance. This includes checking hydraulic fluid levels, inspecting the platform and components, and addressing any signs of wear or malfunction promptly. Routine maintenance ensures optimal performance and minimizes downtime.

Comparative Analysis:

Comparing the performance of hydraulic scissor lifts in indoor and outdoor settings unveils the nuances of each environment. Factors such as maneuverability, lift capacity, and power sources may vary, influencing the choice of lift for specific tasks.

Real-world Examples:

Exploring real-world examples illustrates the adaptability of hydraulic scissor lifts. From efficiently navigating factory floors for equipment maintenance to aiding in the construction of skyscrapers, these lifts have left a mark in diverse industries.

Operator Training:

Ensuring operators are well-trained is integral to safe lift operations. Training programs cover the basics of lift control, safety protocols, and emergency procedures. Competent operators contribute to accident prevention and efficient task execution.

Future Trends:

The hydraulic lift industry continues to evolve. Innovations like smart technologies, enhanced automation, and eco-friendly designs are shaping the future of hydraulic scissor lifts, promising even more efficient and sustainable operations.

the operational versatility of hydraulic scissor lifts makes them indispensable in both indoor and outdoor applications. Their ability to navigate confined spaces with precision and tackle challenges in open environments positions them as essential tools across industries.

- 1. Flexibility and Adaptability

- 2. Cost-Effectiveness

- 3. Enhanced Productivity

- 4. Safety Assurance

- 5. Trial and Error

- 6. Reduced Maintenance Burden

- 7. Accessibility to Advanced Technology

- 8. Environmental Considerations